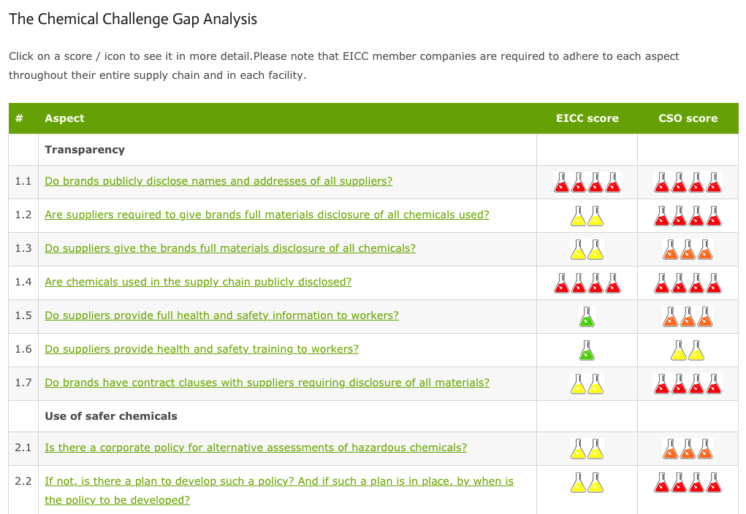

San Jose, November 11, 2016 — This week the GoodElectronics Network and the International Campaign for Responsible Technology (IRCT) launched the online Chemical Challenge Gap Analysis, showing just how far the manufacturing standards developed by the electronics industry fall short of expectations set by experts in occupational health and safety as well as civil society organizations.

Alejandro Gonzales from GoodElectronics:

“We call on the electronics industry to proactively reduce and eliminate human rights violations associated with the use of process chemicals in the manufacturing of electronics products and components.”

Deaths and diseases by chemical poisoning

Exposure to toxic substances causing chemical poisoning linked to increased rates of cancer, reproductive damage, birth defects and other serious illnesses, is increasing for workers on the electronics assembly lines. Companies responsible do not want to be transparent about disclosing the chemicals and toxins their electronics workers are exposed to on the job.

The case of Zhu Yishu

Zhu Yishu worked in a plant which manufactured ICT products principally for Japanese brands, such as Sony, Panasonic and Toshiba. As part of his job, he had contact with thinner, alcohol, solvent naphtha and other chemicals. In 2006 Zhu started experiencing pain in his back, bones and joints and was diagnosed as having acute leukaemia. In 2008 Zhu had a bone marrow transplant but suffered a relapse four years later. He now needs another transplant but the factory is refusing to pay for it. Zhu claims that his workplace was never inspected by clients and when officials from the Centre for Disease Control and Prevention (CDCP) did come to inspect the plant, the manufacturer was notified before the visit and workers were told to conceal things.

To address these problems, GoodElectronics and ICRT published ‘Meeting the Challenge’ in 2015. The Challenge calls on the electronics industry to address six key areas: (1) transparency, (2) use of safer chemicals, (3) protection of workers, (4) participation of workers and communities, (5) protection of communities and the environment, and (6) compensation and remediation.

Next steps with the industry

The Good Electronics Network and the IRTC launched the GAP Analysis at the annual conference of the EICC – an industry coalition dedicated to electronics supply chain responsibility. Around 20 companies, including members of the EICC Chemical Management Working Group attended the presentation including Apple, HP, Sony, Phillips and Texas Instruments. GoodElectronics and ICRT will further discuss the Gap Analysis with the EICC and the members of the Chemical Management Working Group of the EICC in the beginning of 2017.

“In the upcoming discussions, the objective will be to agree on specific priority areas to be improved and then define a road map leading to concrete changes in the entire electronics industry. Some of the potential focus areas include: public disclosure of names and addresses of all suppliers; policies and contract clauses guaranteeing the right to collective bargaining; and policies ensuring suppliers provide fair compensation to workers,”

said Alejandro Gonzalez from GoodElectronics.